Sometimes we get the opportunity to go back to our roots. As a professionally trained precision engineer, specialising in engine remanufacture the chance came knocking last week.

It’s quite rare I get the chance to exercise my skill sets in engineering .why? In a word cost. So what’s the difference between price and cost?

You can adjust the price by several means, cutting corners in labour time, poor preparation, ignoring many of the peripheral repairs necessary for a durable repair.

You can choose to use budget parts

You can adjust your profit margin

You can increase the price by conducting unnecessary work

You can increase or reduce the price and not carry out additional work

But at the end of the day one thing has not changed, and can never change! The true cost of a professional repair!

Its controlled by condition , time required, the parts required, and the infrastructure required to support the repair , by that I mean access to a professional repair workshop and all that entails , a qualified technician , with, not just the necessary skill sets , but perhaps more importantly , the passion to provide a top quqlity , value for money and durable repair.

So if you accept that there are no short cuts, given the complexity of the vehicle as we know it today, why then do so many technicians feel under pressure to compromise based on price. Short term gains will always lead to long term loss. Repeat failure, warranty claims, reputation loss, and unpaid rectification work.

You are the expert! Advise your customer what’s involved, and why, warn against poor quality parts and short term or part repairs. Deal with the causes of the failure and not just reacting to the symptoms or collateral damage. Replacing a blocked dpf with a new one is not the answer and will definitely not provide a durable repair.

So how did we repair this head gasket failure, and deal with the severe emulsification of the lubrication system.

With care, passion and consultation.

I think I will let the photographs do the talking , you be the judge , as a foot note I have been building engines since 1968 , road and race , not one has failed to date !

I would rather cut grass than cut corners.

Brief summary of work\ action undertaken

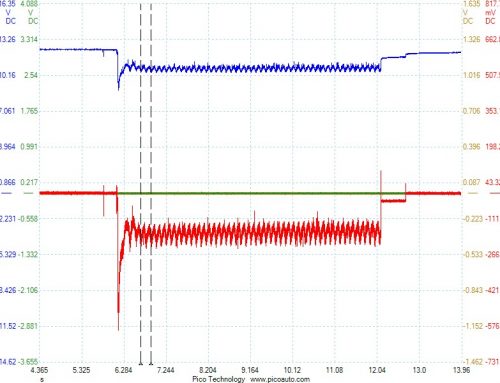

1\ initial assessment

2\ careful inspection during strip down

3\submit head and major castings for rework, chemical cleaning and crack testing

4\ oil pump\pressure relief valve\oil pickup gauze fully striped

5\engine block and entire engine bay hot pressure cleaned

6\ coolant system steam cleaned\ note previous blockage in cylinder head face

7\ cylinder head face cleaned \checked for distortion

8\ all parts thoroughly cleaned\ new nuts, bolts where required

9\ replacement of all special parts\ head, cam crank stretch bolts,

10\total replacement of timing assembly

11\ reassembly of engine and ancillary components

12\ all service parts replaced

13\ engine run with flushing oil

14\ oil filter replaced

15\ correct oil fitted

16\ vehicle test driven, dtc log cleared\ all fluid levels checked

17\full valet

18\ full report and photographic record presented with invoice

19\ hand over to customer by technician responsible

Official book time 5.5 hrs

My time booked and charged 10.5 hrs.

End result, quality repair and Happy customer.

Fantastic repair, just how I would do it but 10,5 hours ? take me a lot longer than that I am sure !

Thanks for everything. You are doing the best to inform us about being a technician and good mechanic

My two sons who are “time served” plumbers spend most of their time correcting faulty workmanship done by other “amateur” plumbers . It’s time a full apprenticeship was brought back so that people can get “value for money” again. I had to go to nightschool for a full five years before I was accepted as “Qualified” having done almost every type of plumbing during my apprenticship.

Franks sentiments and ambition is to be commended, however the true facts are that a large cross section of the Uk’s franchise and independent garages do not want the responsibility of assessing the parts to be changed or machined on this type of repair and then having to warrant the whole repair. This is why Motorman is requested to supply or supply and fit fully re-manufactured aftermarket replacement engines for Car/ Van and LCV applications, all supplied with 12 months full national unlimited mileage warranty by fleet operators across the country.

When operating vehicle’s for business the key drivers are not always cost, more often than not its quick turn around and reduction to the exposure of risk by acquiring a quality tested unit with solid robust warranty.