The New Year brings an exciting start to our new training facility at our Preston workshop. Dedicated diagnostic bays run side by side with our commercial repair facility. Training can now be conducted in real time within a live commercial environment, we believe this is a unique opportunity for trainees as well as research and development for our new training courses.

The New Year started with a request to repair a rover 75 2 litre diesel. As a vag brand specialist we almost turned the offer down however the fault appeared to relate to the common rail system. Common rail repairs are one of the specialist services we offer so here is the account of what turned out to be an interesting challenge.

The vehicle was presented as a non-runner from recent attention by a rover specialist. Our initial concern was focused on the fact we didn’t have total serial access via test book. We have always advocated that total vehicle serial access is vital.

Access to serial data suggested a wiring or component failure, fault codes relating to the drv (diesel regulating valve), camshaft sensor, heater plug control module all shared a common supply via a relay and fused circuit.

However when checking the voltage with our Pico all appeared ok! The faults cleared. The next test focused on hydraulic functionality. The Bosch cr system should provide a static rail pressure voltage of 0.5 volts rising to approx. 1.5 volts cranking, depending on correct priming, hp pump efficiency, and system leakage.

Initial tests showed no increase in voltage whatsoever when cranking the engine. At this point it is vital & prudent to check for a control signal at the drv. Without this the only pressure able to be produced is approx. 60 bar. This is achieved via the closure spring in the drv. So no pressure, no minimum rail pressure enabling the injectors to be triggered & no start.

Let’s recap so far without an absolute minimum rail pressure, relating to 1 volt, approx. 260 bar the ecu will not release the injectors. Possible causes no priming, hp pump control or a system leakage.

Next we attach our priming gauge (we have designed and have built to our specification, gauges to accurately test pressure, peak max & flow) the test confirmed a healthy 5 bar supply with no cavitation.

A very common cause of this symptom is a ruptured control seal on the drv, many suppliers will try to sell a complete pump when all you need is a repair kit or a new drv. So off with the drv on with a new seal. A repeat cranking test now confirms a small increase in pressure? At this point I decided to kill or cure, we have a special tool which is able to control the pump independently of the ecu.

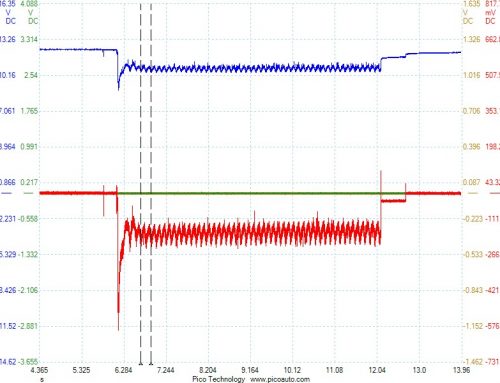

This test confirms a peak pressure of 4.5 volts or 1350 bar spot on for this system. So we have a good pump, why no start? A quick back leakage test proves good, so back to the drv control signal.

It was there! I did scope it, now it’s only got around 5 volts supply? And you all know actuators need nominal battery voltage to carry the necessary current. In our case the current range is 0.6 amps @300 bar and 1.6 amps @ 1350 bar. Back to my original opinion a wiring fault with the power supply to several key & critical components.

A quick check of the current flow schematics suggested a voltage drop before the relay and fuse both of which were checked and excluded from the problem list. Raising the fuse box assembly quickly identified a chaffing of the loom on the near side light cluster.

I spliced and reinforced the loom preventing future issues, the car started promptly and ran smoothly. Job done, overcame Glyn our mechanical guru asking what I found, strutting like a peacock I preceded to start the vehicle, and it didn’t start!

You know what, it’s like walking back out of a mine field you have strayed into, just retrace your steps very carefully. Rail pressure excellent no injectors, confirmed by measuring current not voltage. The injectors require an initial timing sync from the cam sensor, and it wasn’t there, power & ground were good so it’s a simple double fault cam sensor failure,

It was a good start to the New Year reinforcing, good process, a logical diagnostic path and reliable system information. A final sting came when the 15 amp control fuse failed, almost certainly due to the short overload.

Leave A Comment