I love the word misfire, it’s the most misused expression in the technician’s vocabulary! Simplistically it falls into 3 categories,

1. Ignition malfunction,

2. Mechanical faults,

3. Fueling errors.

There we are all done end of topic……well not quite, let me spend the next 700 or so words expanding on why & how. Combustion failure or anomaly is the correct expression. It expands on the whole range of options that can cause incomplete combustion.

Mechanical problems,

Engine development now includes variable valve timing on all cams, variable lift, much of which depends on hydraulics & or electronic actuators. Incorrect oil specification or service intervals are prime causes of valve timing errors. Many also have flexible oil pressure control with pcm mapped piston cooling. Direct fuel injection requires precise fuel delivery, this includes induction turbulence control. Intake ducts, flaps and valve gear often suffering carbon contamination, a very common cause of transient throttle combustion malfunction. Worn valve guides effect critical pressures in the combustion preparation phase.

Solution,

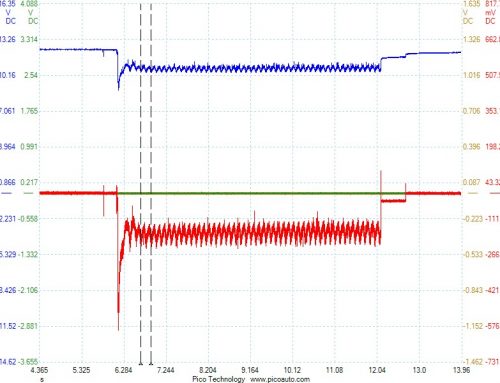

Careful interpretation of PID’s especially adaptive correction values. conduct a real time absolute cylinder pressure evaluation, using the Pico WPS. Note my choice in words carefully! As there is no such thing as vacuum, it does not exist! its pressure differential relative to atmosphere. The falling piston creates an increase in volume there for a change in pressure. This change is referred to as the expansion void. Careful scope examination will expose discrete anomalies in the operation of cams and valve gear. The two voids indicate intake efficiency and valve overlap map timing.

Fueling problems,

Fueling maps now include infinite control deviation. stratified& homogeneous delivery, split injection timing on both intake & compression strokes. Sequential quantity correction, current correction, and simple trim deviation. the injectors must atomise the fuel correctly across a pressure range 40-200 bar. The inductance values are a precise requirement if opening & closing timing is to be met. The introduction of port and direct injection to reduce particulate emissions introduces complex fuel mapping of timing, quantity, delivery method & pressure.

Solution,

Detailed evaluation of fuel trim characteristics, cylinder deviation, timing set back, and exit temperatures. Removal of injectors and precise testing with an ASNU bench.

Ignition problems,

So finally, we arrive at the easy bit! Think again, not only does the ignition system must generate the correct energy required for complete combustion it must deliver it totally. I don’t subscribe to the manufacturers plug life guide as it has no allowance for operating environment deviation, fuel quality or servicing regime. I own a seat cupra 280, the official plug replacement interval is what? Answer at the foot of the topic. Plugs must now be torqued so the angle of the electrode is correctly aligned with the injector. Ignition control is also sequentially mapped and corrected, knock monitoring, exit temperatures, lambda data, are just some of the variables as well as multiple strike features.

Solution,

Although serial data offers some insight into ignition performance such as extensive misfire monitoring it does not provide definitive diagnostic evidence. Four critical elements in order of importance are,

1. Ignition burn time, the precise length of the energy cross over. Its effected my many of the previous problems, notwithstanding its passage through the fuel air mixture, expressed as slope and turbulence.

2. Primary current control, the inductance in primary is vital for correct secondary energy generation. The saturation time “dwell” controls current flow & peak value, but it’s the speed and nature of magnetic field interruption that ensures good induction.

3. Coil ringing, the symmetrical pattern at the end of the burn period qualifies the condition of the coil windings, condition as well as good insulation. 4/ firing line voltage, the net value of energy required to overcome the path between the coil and the spark plug. It’s the physical circuit as well as the plug condition and can be effected by in cylinder environment changes.

Solution,

Pico scope evaluation using voltage and time evaluation of spark profile and primary current path assessment, there is simply no other way. It’s vital that knowledge of specific system values is known as they differ across system types.

Conclusion,

I guess I should leave that to your private thoughts and needs,

Hope to see you soon! oh yes, the answer 6 years.

Leave A Comment