Firstly I’d like to offer my sincere apologies for the big delay in writing for Auto inform but the new arrival of my daughter Sofia eva-jean Massey has somewhat used up any free time I didn’t have before.

The work shop has never been as busy and we’ve taken on a new member of staff so all is going well and we’re due to move premises into a much larger and bespoke building sometime before Christmas so it’s been all hands on deck at ADS headquaters.

This week workshop topic tackles a very interesting and potential headache of a car.

The named offender is the impressive and equally formidable E92 BMW 335d twin turbo brought into us with a complaint of intermittent lack of power and excessive smoke out of the exhaust and upon initial serial diagnostic check provided only one dtc’s stored for Air mass meter.

Now this is where it gets interesting, under normal operating conditions this vehicle can present a whole host of challenging problems and diagnostic headaches.

In this case I wasn’t so lucky, this car was presented into my workshop after spending the last 6 months having every component apart from the chassis replaced and fiddled with. I personally took several phone calls being asked for guidance over this period so I was able to track the ‘repair’ if you can call it that.

The chief technician in charge of the repair inevitably asked me how much to tell him what’s wrong and how much it would take to fix it. Good question I replied.

We know it’s not easy or in fact possible to exactly determine how much an accurate diagnosis and subsequent repair will cost especially given the extensive work history. Many of you out there might even choose to completely avoid such jobs and I don’t blame you.

But if you’re honest, open and upfront there’s absolutely no reason why you can’t earn decent money at diagnosing and rectifying such problematic cars. Realistically if I was to turn away every car which had been messed around with before we got it I would have gone out of business a long long time ago and you’d probably find me running the country or cutting grass by now, Probably the latter.

In this occasion I agreed 3 hours diagnostic work @ £102 per hour to check correct installment and operation of the turbo plus £400 eventually for correct software tune.

Firstly both Turbo’s had been replaced at least twice for cheap alternative reconditioned units from an unknown source.

The first Turbo replacement was prompted due to mechanical seizure of the main shaft in the housing inevitably and likely to be caused by poor maintenance!

By the time it was presented into my workshop both Turbo’s had been replaced along with all the corresponding oil feed pipes, cam cover breather and usual service items related with Turbo replacement repair.

The DPF filter had been removed; this was obvious by the scars left on the outer body of the DPF.

Besides the legal implications of the DPF filter being removed it wasn’t obvious whether or not the software in the ECU had been correctly setup to cope without the DPF.

Let’s leave legality out of this for a moment and just talk technically.

I have witnessed many botched DPF removal jobs which have presented themselves into my workshop whereby only the DTC’s related to DPF blockage have been removed. Many of the cars hadn’t had the regeneration strategy or indeed the turbo boost profile adjusted.

Remember the DPF acts as a blockage or restriction in the exhaust and once removed will have a dramatic affect on turbo boost profile.

If you data log boost on a vehicle initially equipped with a DPF from the factory then remove it, you will end up with a massive initial overboost situation and end up with what’s best described as an asthmatic turbo not being able to cope with demand due to lack of back pressure.

When fitting a free flow exhaust system to any vehicle petrol or diesel it’s absolutely critical you have the boost map correctly adjusted otherwise you severely jeopardize the longevity of the turbo not to mention ruin drivability and performance.

I don’t need to tell you as I’m sure you’re all aware the market has sprung up like fungus a new breed of ECU flash tuners advertising DPF removal/quick cheap re maps from as little as £150 !!

Don’t get me started on this band of special idiots I’ll be sat here all night.

We all know the key to successful diagnostics that in order to carry out any repair on a system is that we fully understand exactly how it works and once we have developed that understanding, fixing it should be easy ! Right?

Now back to the BMW, I’ll stick my hand up now and say until recently I hadn’t worked or even fully understood how the BMW 335d turbo system worked and was unable to acquire any proper data from anywhere. So I did plenty of workshop good old fashioned R+D to develop a comprehensive test plan to hopefully help you guys.

Now firstly I want to explain exactly how the system is compromised and works by using pictures I stole from the internet.

Basically it’s a fixed vein small Turbo which feeds a big fixed vein Big turbo which uses a wastgate.

None of these two turbo’s are variable vein which I was completely unaware of until now.

The flow of Air and control of these turbos are regulated by a series of flaps, one in the exhaust and one in the inlet.

Bare with me.

You can simplify their control by separating the process into 3 clear section

- Low RPM

- Mid RPM

- High RPM

During low engine speeds only the small turbo is engaged offering instant, sublime low down engine torque and power delivery.

During mid range both turbos are in operation and when moving at high speed only the big turbo operates and this is how it’s achieved.

Key points

At low engine speeds both bypass valves are closed forcing the air solely through the small turbo charger.

When you start to hit medium RPM the exhaust valve labelled A. is opened forcing the air through the larger turbo pre-charging the air into the small turbo then into the engine.

When you hit high engine speed the bypass valve B is opened forcing exhaust gas through the larger turbo enabling warp drive and time travel.

Just in case you didn’t understand that here’s a video of a smarter guy than me explaining it brilliantly.

So now we know how it works I’m going to show you how to diagnose and test each component.

It’s easy on a job like this and not know where to begin and I sometimes have to stop myself from diving in which inevitably leads to mistakes.

Firstly I acquired myself a diagram which labelled the precise order in which the turbo control system was plumed together. There is a labyrinth of vacuum control hoses which not only deteriate over time but decide to move location flitting between components all by themselves.

Here is another diagram I stole from the internet.

Naturally I went through each and every single connection one by one to ensure correct fitment and to my surprise they were all absolutely spot on.

However the inlet bypass control pipe had been fit incorrectly and run through 90 degrees before it fitted onto the control solenoid making it crimped and restricting control vacuum.

I quickly re fitted the control hose and tested control functionality to all corresponding valves and wastegate.

I was abale to do this using the Autologic handset but don’t worry if you haven’t got access you can simply use your vacuum guage and mitivac to test each component.

The Autologic enabled me to select each component individually and drive it in sequence, it even gave me the precise movement ratio to be expected from each actuator.

- Exhaust bypass valve A. 25mm

- Inlet valve B. 15mm

- Turbo wastgegate valve 5mm

When I initially tested the wastegate valve with a mitivac I yelped Eureka thinking I’d found the problem as I witnessed the wastegate only slightly opening nowhere near that of a petrol turbo wastagate that we’re all used to. The correct opening travel is only 5mm !

If you’re sneaky and whilst using a torch you can just see the actuator arm right down the back of the exhaust manifold, altalternatelyu can remove the under tray for a proper look. I’ve stuck my screw driver to point out where you can see the arm.

With the engine running you can very easily see the main exhaust valve opening and closing in front of your eyes but as for the smaller and hidden inlet valve towards the fron you have to listen and detect a change in engine note whilst operating.

Using the vacuum guage I checked healthy vacuum operation at each component to ensure good control which varied between 0-20 inhg.

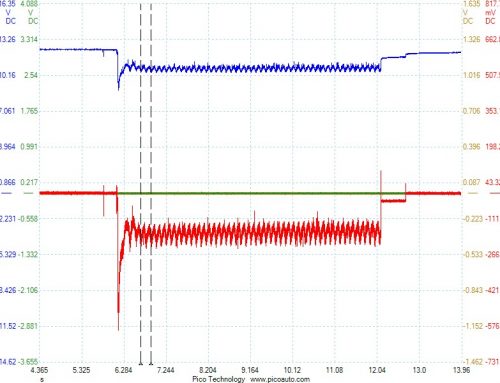

Confident I had checked every single turbo control valve and rectified the small issue with the vacuum control hose controlling the inlet valve a carried out a wide open throttle test and measured calculated air flow.

The engine responded much cleaner but soon deteriated and produced an unhealthy cough of black/blue smoke and idle speed quickly deteriorated with the engine giving off a noticeable aquistic deep sound.

Keeping things simple I checked the target calculated Air flow against actual air flow and very quickly it was clear there was a problem.

Using the mitivac I was abale to manipulate the EGR position to allow the correct reading and desired engine note.

The valve itself was free and able to move willingly but for some unknown reason the ECU wasn’t controlling EGR as normal.

It was at this point I simply decided to completely bypass the EGR through ECU calibration and software adjustment also making the necessary adjustments to boost control and DPF regeneration program.

(for track use only)

After EGR was removed the car ran brilliantly and smoothly !

You might all be wondering why I didn’t go straight for EGR in the first place as it’s so easy to test but it’s so tempting to get side tracked and lose focus of your repair.

I’m glad I spent all the time to carefully check the Turbo control system a. because I was getting paid to and b. I learned a great deal about these systems and I hope I’ve helped you with this topic.

Thank you for reading. J

My next article is bonkers and you’re going to be convinced I’m bonkers for even taking it on. To wet your appetite it involves a none starting 204 chassis Mercedes c class which let’s just say has been used to launch full amphibious assault on Normandy.

Hi David

Thanks for article.

Just letting you know that for what ever reason pictures are not poping up at all.

Regards

George – Q.Q.M.R.

Hi

Finaly I’ve faund Your post which help me solve my Car !!!

Fight with almost a month and can’t understand why DDM have problem with EGR valve.

Now , think best way just to throw it away.

All the best

Matt

Good read, I’m interested in the part “During low engine speeds only the small turbo is engaged offering instant, sublime low down engine torque and power delivery” I have the same motor but lacking power during low engine speeds, changed out oily boost hose but still have the same issue, any pointers on this ? Cheers